欢迎进入蓝能官方网站!

【电话热线】020-34154005

抖音扫码关注

微信扫码咨询

【手机微信】13922491768

020-34252975

产品中心

Products Center

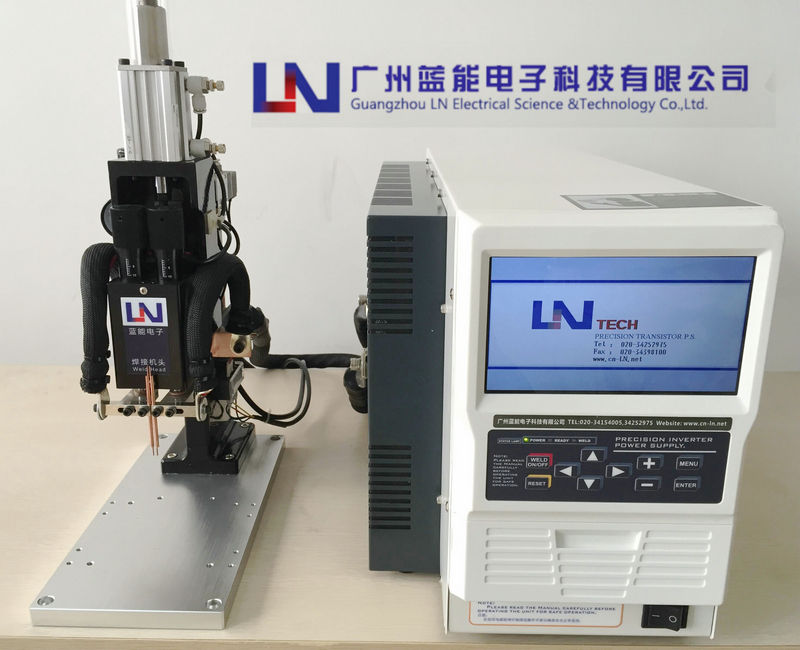

晶体管点焊机

晶体管式焊接电源最适合于微小部品的精密焊接。特别是航空继电器,传感器,电池等行业应用较多。

Transistor type welding power supply is suitable for precise welding of superfine wires and micro components.

晶体管式焊接电源特点 Feature

l 200KHZ超高频精密控制,焊接电流上升速度快,可在短时间内实现高品质焊接!

l 四种控制模式选择:次级定电流、定电压、定功率有效值及混合定模式

l 极性切换型电源,可实现焊点均匀,电极消耗少,降低帕尔贴效应的影响,使焊接的焊斑保持均一(电池镍片等单面双点焊焊接时,两点完全一致)。

l 中英文操作界面;7寸彩屏实时监测显示焊接数据和波形,可显示焊接压力(配合LOAD CELL);存储63组焊接规范;

l 丰富I/O接口,适用于各种自动化生产领域;多种通讯协议(RS232、RS485总线,以太网);

l 50-100 KHZ UHF precision control, welding current is rising fast, high quality welding;

l Four kinds of control mode selection: constant current, constant voltage, constant power and mixed mode;

l Polarity switching type power supply, which can realize uniform solder joints, reduce electrode consumption, reduce the Peltier Effect, keep the welding spot homogenous;

l In both Chinese and English operation interface; Seven inches color screen real-time monitor display welding data and waveform, can display welding pressure (with the LOAD CELL);63 groups of welding specification;

l Rich I/O interface, suitable for all kinds of automatic production areas; a variety of communication protocol (RS232, RS485 bus and Ethernet)。

晶体管点焊机技术规格 Specification

型号 Type | LNDB-6500A | |

最大电流Maximum current | 6500A | |

30V | ||

控制方式 Control Method | 次级定电流、定电压、定功率有效值及混合定模式 constant current, constant voltage, constant power, constant pulse width | |

电流设定范围 Current setting range | 0.03A—6.49KA | |

电压设定范围Voltage setting range | 0.3—9.99V | |

功率设定范围Power setting range | 0.3—99.99KW | |

时间设定Time | 加压时间 Pressure | 0000—9999ms |

上升时间 Up | 0.00—9.99ms | |

焊接1时间Weld | 0.00—9.99ms | |

冷却时间Cooling | 0.00—9.99ms | |

焊接2时间 Weld | 0.00—9.99ms | |

下降时间 Down | 0.00—9.99ms | |

保持时间 Squeeze & Hold | 0000—9999ms | |

监控显示Monitoring Display | 通电1/2规范号、时间、电流/电压/功率有效值及波形、压力有效值及波形、阻抗值 Time; Current/Voltage/Power waveform | |

单相200-240VAC 50/60HZ | ||

外形尺寸Size | 620mm(D)*250(W)*330(H) | |

重量 Weight(KG) | 28 | |

晶体管点焊机

外观均一的焊接强度Consistent with the welding strength

高速焊接。快速电流起动和高速极性切换的功能可以减少焊接时的热影响,得到漂亮的外观。

High speed welding. Fast starting current and high polarity switch function can reduce the welding heat affected, get a beautiful spot.

极性切换功能 Polarity Switch Function

抑制焊接点的不对称,得到均匀的左右焊接点的强度。另外,良好的热平衡效果也使电极的寿命延长。

焊接点不对称的影响:焊接时正负极的发热效果不同对焊接强度和电极的消耗影响很大。

对策:避免此现象的产生需要极性切换功能使正负极的发热效果一致。

电池焊接专用晶体管点焊机

-

联系我们

-

售后服务

技术支持

焊接件结构建议,可行性分析,焊接工艺、 设备方案、焊接结果检测技术服务支持。

及时服务

24小时及时响应客户的问题反馈。

售后服务

设备交钥匙服务品质,现场陪产、设备维护 保养、设备应用工艺扩展全面技术服务。

微信扫码咨询

抖音扫码关注

视频号扫码关注

公众号扫码关注